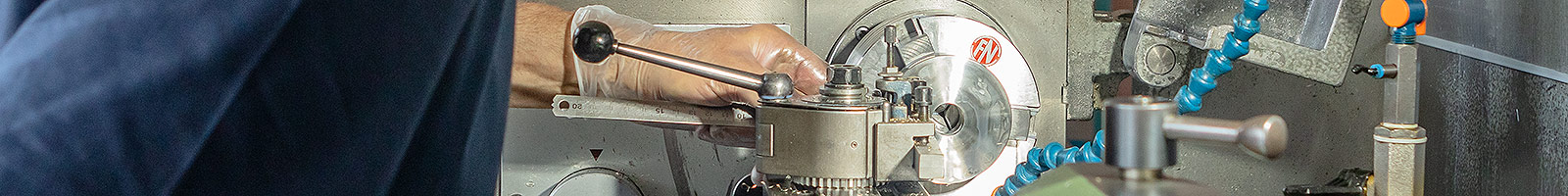

We have developed our own solutions to increase the productivity of Tornos, Bechler and Strohm cam machines and guarantee a significant return on investment.

Do you want to calculate your return on investment? Send us the drawing of a part and we will calculate how much it costs to produce it on our machines.

-

Basis: Bechler AS-7 / AS-10 / AR-7 / AR-10 (MIDI)

Transformation of your Swiss Automatic Lathes in high speed machines with:

- New high speed RSC spindlestock

- Slides scraped flat or reground

- Central lubrication of spindlestock

- Central lubrication of slides and axles

- Reconditioning of entire machine

Equipment :

- Original base of the machine

- Machine totally enclosed by three sliding guards according to CE norms

- Programmable controller

- Continuous adjustment of the spindle speed from 500 to 20,000 rpm

- Camshaft driven by servomotor

- Setting of the production rate from 0.1 to 40 parts per minute

- Variation of the spindle speed of the spindlestock

- Easy-to-use control panel

Diameter of bar:

- 1 to 6.35 mm

- 6.35 to 10 mm

Types of machine:

- Modification of all Bechler machines with motorisation

-

Basis: Tornos M7 / MS-7 (MAXI)

Transformation of your Swiss Automatic Lathes in high speed machines with:

- New high speed RSC spindlestock

- Slides scraped flat or reground

- Central lubrication of slides and axles

- Reconditioning of entire machine

Equipment :

- Rectangular machine base with flat sides

- Machine totally enclosed by three sliding guards according to CE norms

- Capacity of the cutting oil tank 50 litres.

- Large capacity swarf hopper (40 litres)

- Programmable controller

- Continuous adjustment of the spindle speed from 500 to 20,000 rpm

- Camshaft driven by servomotor

- Setting of the production rate from 0.1 to 40 parts per minute

- Variation of the spindle speed of the spindlestock

- Easy-to-use control panel

Diameter of bar:

- 1 to 6.35 mm

- On the MS-7 up to 10 mm

Types of machine:

- Modification of all Tornos machines with motorisation

Retrofit Tornos M7 (Youtube movie)

Documents to download

| Documentation Bechler Lathes | PDF / 808 Ko |

| Documentation Tornos Lathes | PDF / 721 Ko |

| General conditions of contract for the supply of plant and spare parts (EN) | PDF / 735 Ko |

| Condizioni generali di fornitura per macchine e parti di ricambio (IT) | PDF / 732 Ko |

| Condiciones generales para el suministro de maquinaria y repuestos (ES) | PDF / 743 Ko |